Precision Prototype Customization CNC Processing Services

Get Latest Price| Transportation: | Ocean,Land,Air,Express |

| Port: | ShenZhen |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShenZhen |

Brand: JKP

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

The file is encrypted. Please fill in the following information to continue accessing it

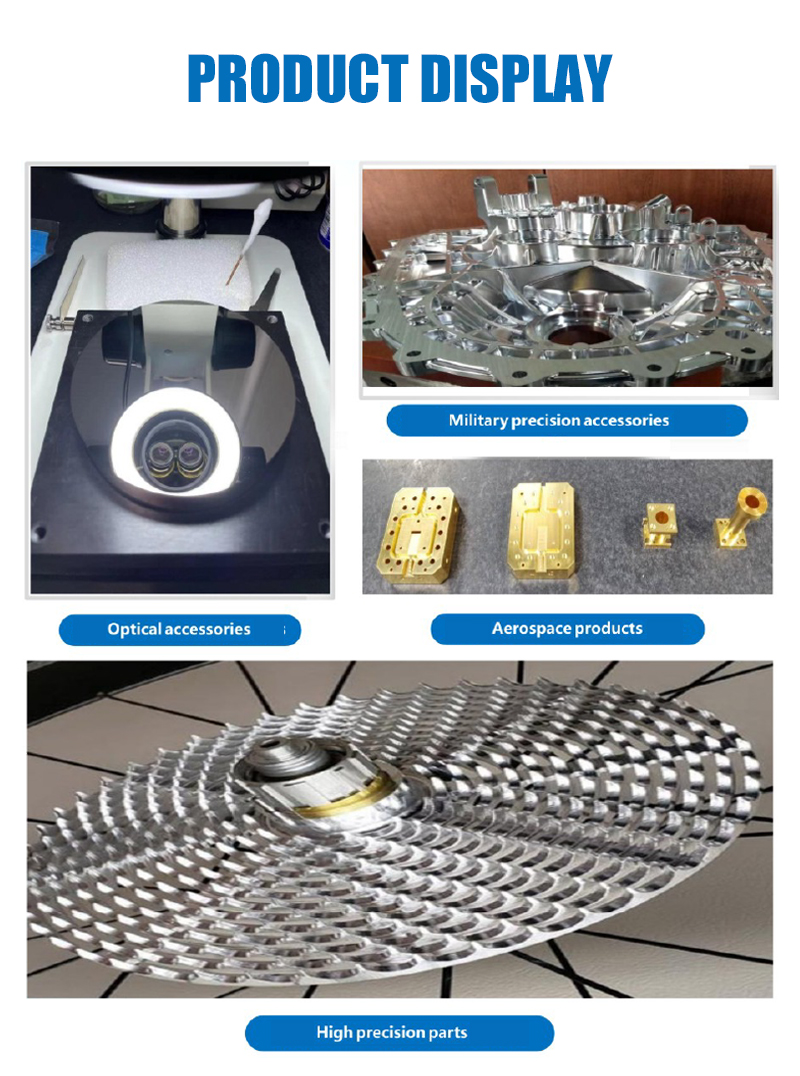

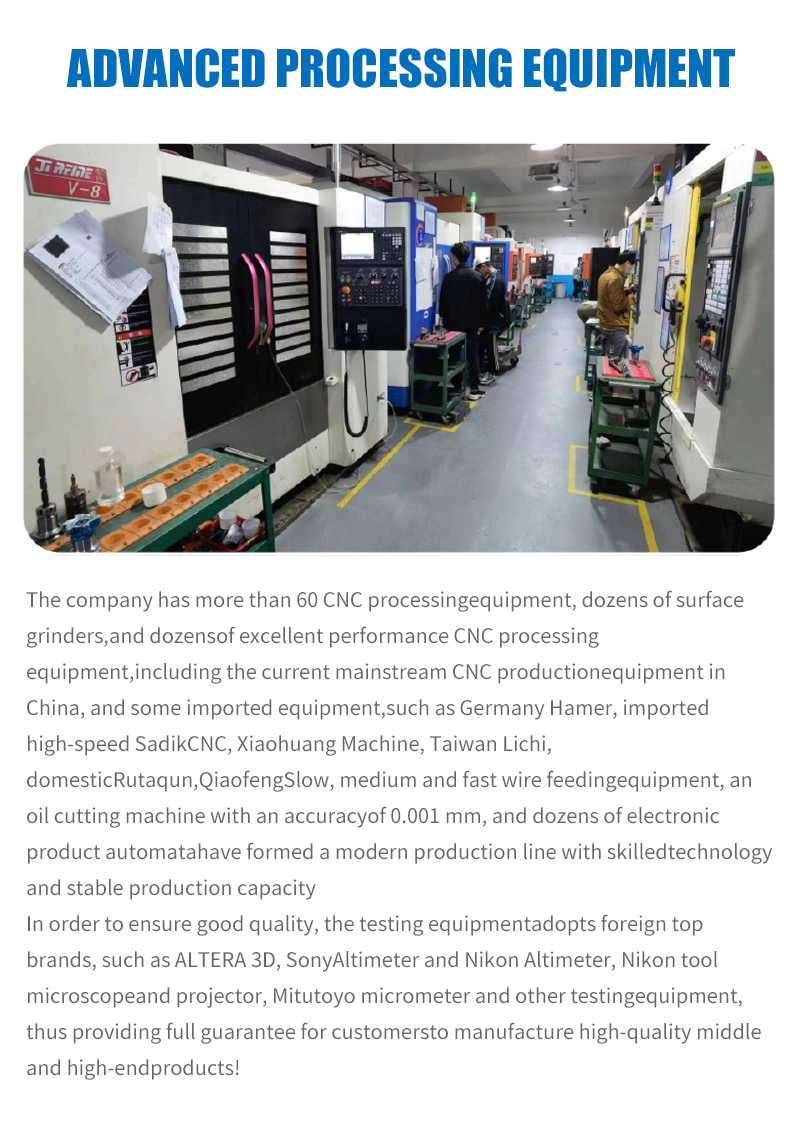

Our company offers Precision Prototype Customization CNC Processing Services,3D Printing Services and specializing in Micro Precision Machining Parts and High Precision CNC Milling Machine. We provide high-quality 3D printing services that can quickly print accurate prototype models based on customer provided CAD drawings with using advanced CNC technology to ensure high precision and quality,which helping customers save time and costs.

1. High cost: This has the effect of making the overall cost of acquisition and subsequent maintenance rather on the high side, not to mention the fact that programming and operation of the system requires professional skills that are in short supply.

2. Complexity: Neural Network, involves basic or complex programming and set-up time, difficult to learn.

3. Limited flexibility: Design modification leads to programming and small scale run may not be as suitable as the standard using of machine tools.

4. Risk of malfunction: Company has a computerized operations flow and this can cause shut down.

5. Safety risks: Consequently, the high speeds and the degree of automation of the handling processes entail high levels of operational risks.

6. Environmental impact: Possible generation of pollutants such as noise and dust may be another disadvantage closely related to the former.

7. Rapidly updating technology: Constant need to upgrade the installation and equipment, with the cost of hardware and software technologies continually reducing.

On the flip side, CNC machining is efficient; however there are factors such as the cost, complexity, and flexibility that needs to be compared.

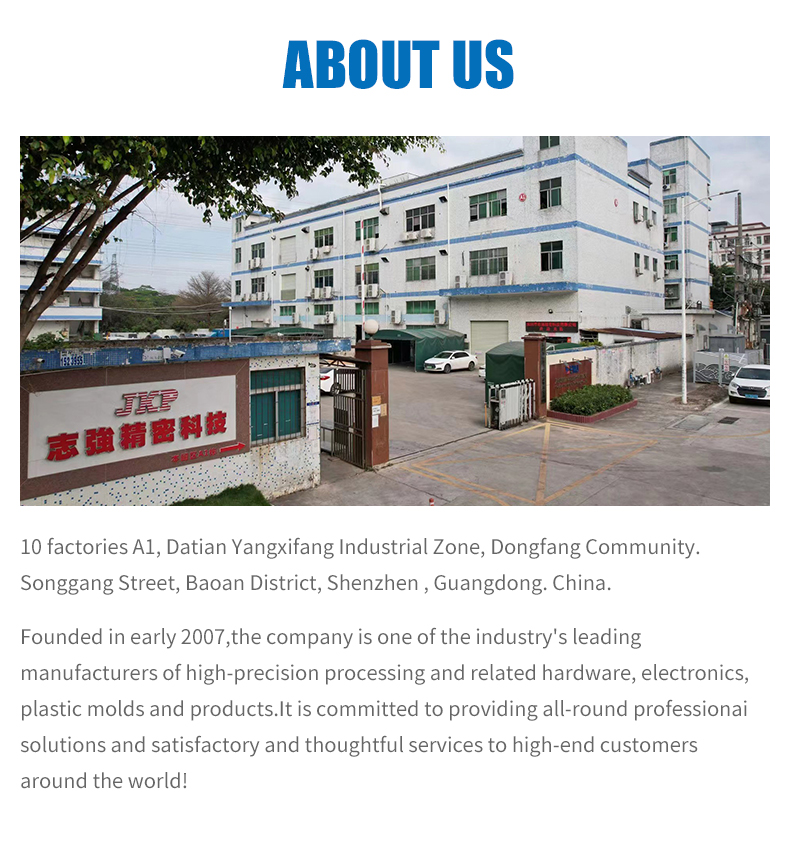

Founded in early 2007, the company is one of the industry's leading manufacturers of high-precision Precision Machining related hardware, Precision Parts,electronics, Plastic Injection Molds and products. It is committed to providing al-round professionalsolutions and satisfactory and thoughtful services to high-end customers around the world!

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.