High Precision Manufacturing Automotive Precision Parts

Get Latest Price| Transportation: | Ocean,Land,Air,Express |

| Port: | ShenZhen |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShenZhen |

Brand: JKP

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

The file is encrypted. Please fill in the following information to continue accessing it

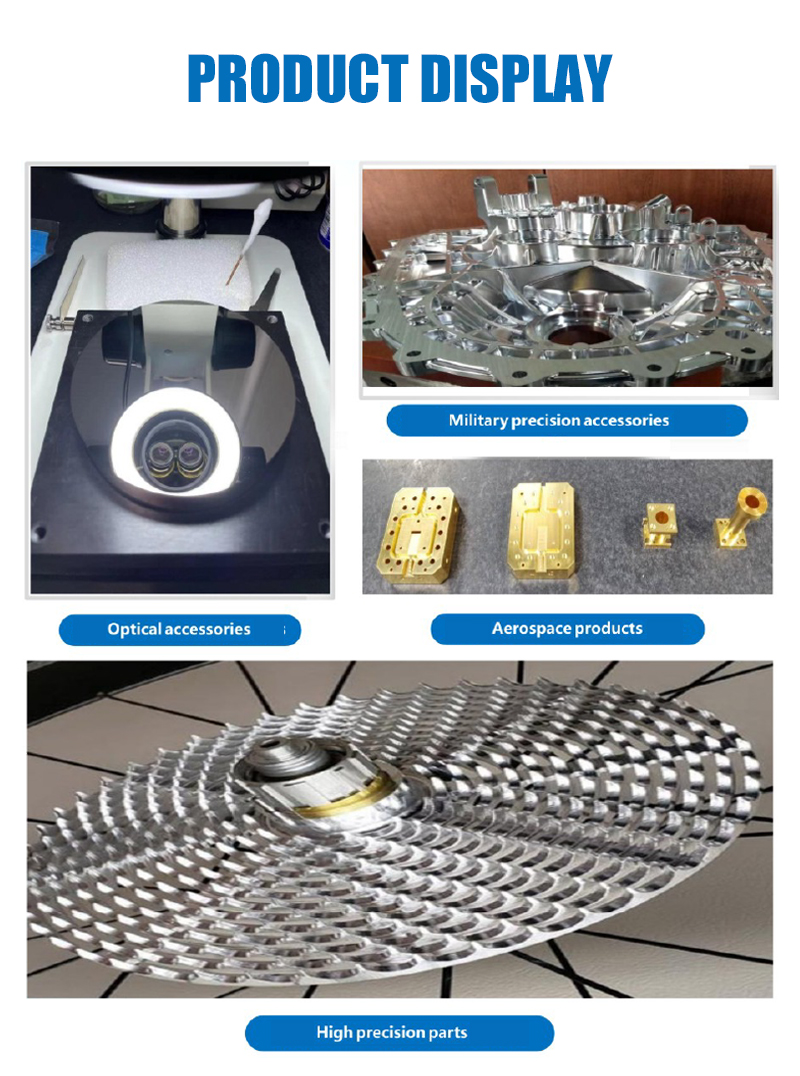

High Precision Manufacturing Automotive Precision Parts: Our cooperative stamping plant has advanced stamping equipment that can produce various complex shaped stamping parts.According to the customers’ needs,we can produce the Precision Turned Components, High Precision Automotive Precision Parts and other Precision Parts.We can choose suitable stamping processes according to customer requirements to ensure the quality and accuracy of the parts.

How to assess whether a part is suitable for the CNC Stamping process?

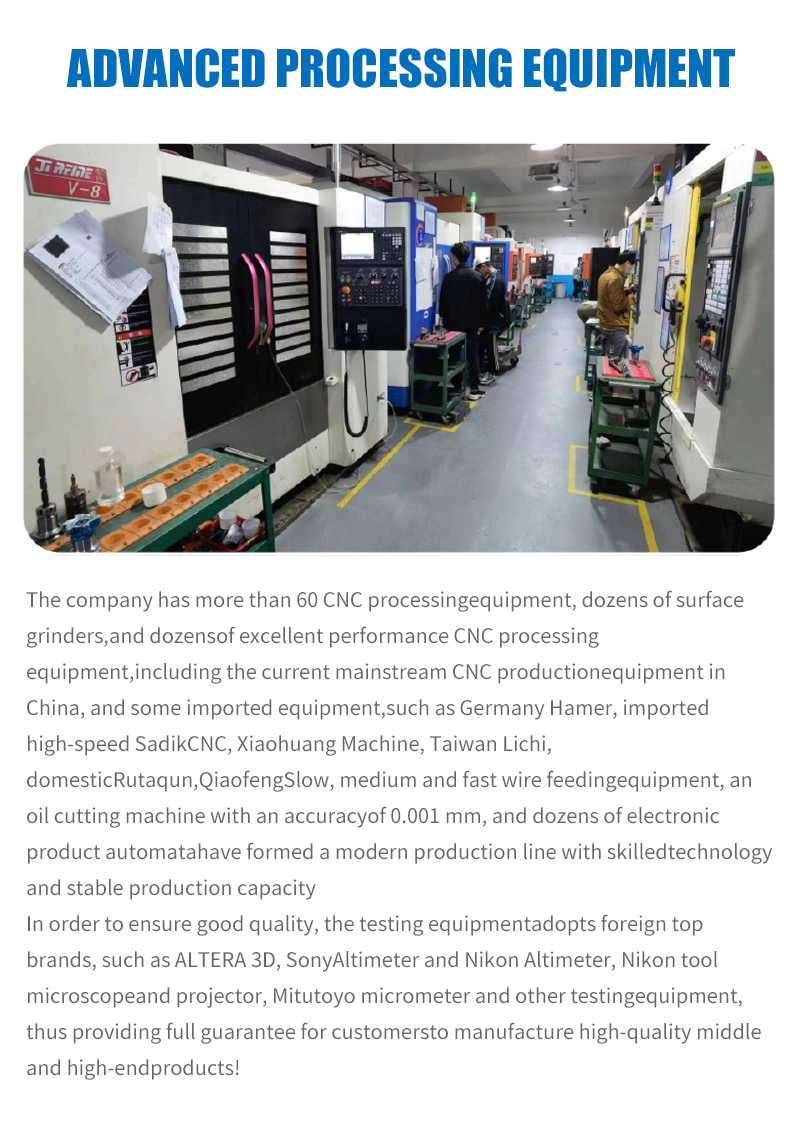

1. Material properties: Whether there is one that would require good plasticity and ductility of the material used for the part so it would not crack during the CNC stamping. Also, the hardness of the material, thickness of the material, as well as the chemical composition will also affect the machining results.

2. part size and shape: CNC stamping is suitable for accurately and efficiently making parts with intricate shapes and finer surfaces on it However, for parts that are more simplistic or for parts that are beyond the manageable size and density, CNC stamping becomes rather expensive.

3. Production quantities: While adopting CNC stamping is a big bonus for businesses that require high quantities of a single product, for small lot or one-off products, there are more cost-effective ways of manufacturing that can be used.

4. Precision requirements: CNC stamping can be made with a higher degree of accuracy and reliability, but for maximum precision it can be necessary the subsequent finishing.

5. Cost budgeting: However, to gain the complete idea of the advantages of using CNC stamping, the operating costs like mold development, depreciation of the machine tools, energy usage, and the labor charges must be considered.

6. Production cycle: CNC stamping is not very time-consuming in terms of production as compared to the other forms of production hence ideal for projects that require short periods of production. However, where available, one may have to use other faster production cycles depending on the time available that may range from a day to even a week or more.

7. Subsequent processing: Whether the part has more processes including heat treatment, surface treatment and so on and whether these processes can be integrated into the CNC stamping process.

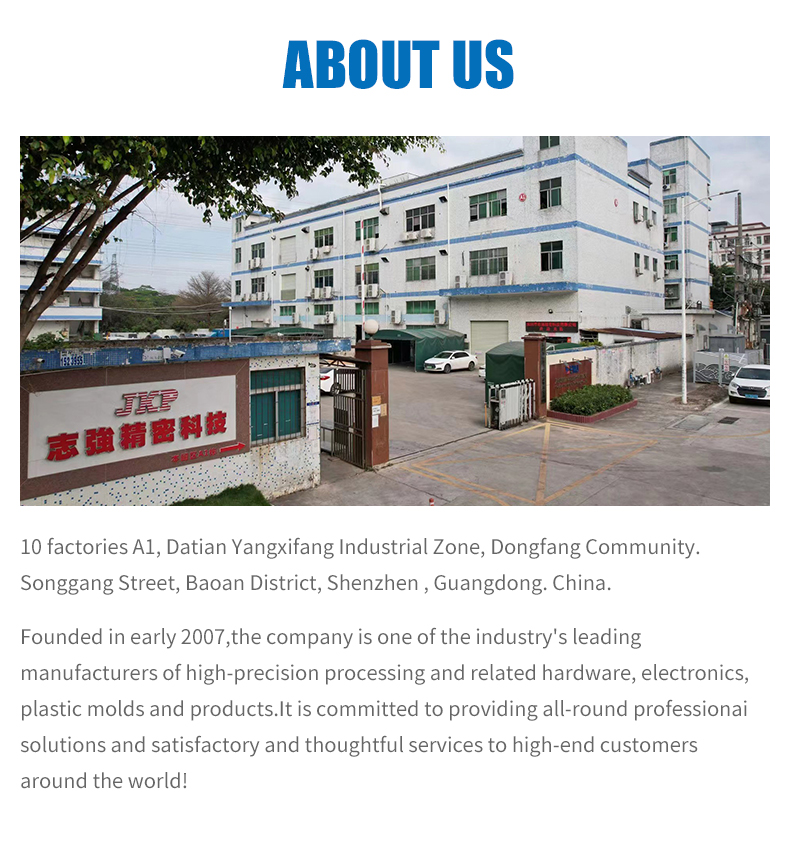

Founded in early 2007, the company is one of the industry's leading manufacturers of high-precision Precision Machining related hardware, Precision Parts,electronics, Plastic Injection Molds and products. It is committed to providing al-round professionalsolutions and satisfactory and thoughtful services to high-end customers around the world!

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.