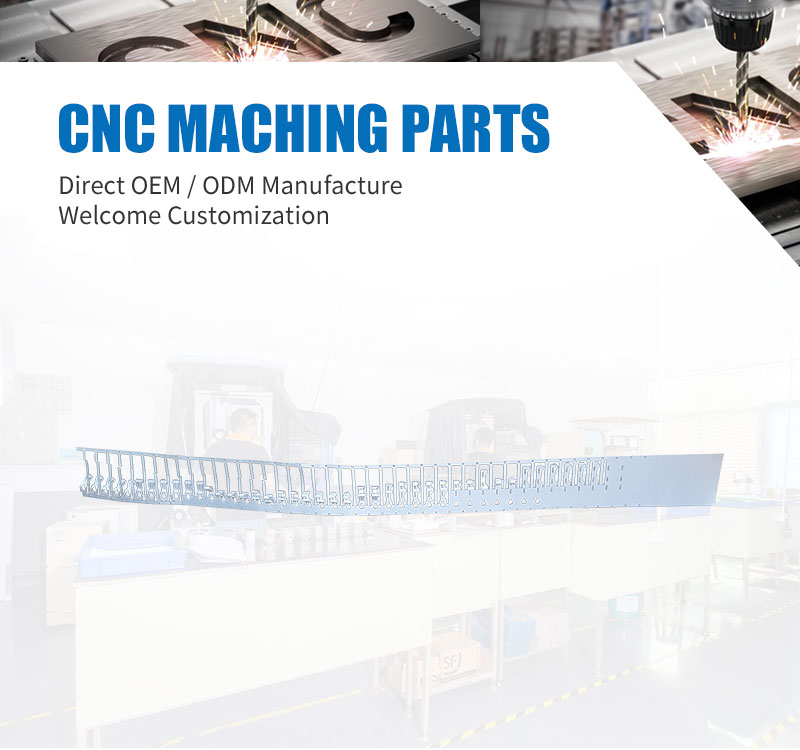

CNC Machining Parts Precision Hardware Spring Stamping

Get Latest Price| Transportation: | Ocean,Land,Air,Express |

| Port: | ShenZhen |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShenZhen |

Brand: JKP

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

The file is encrypted. Please fill in the following information to continue accessing it

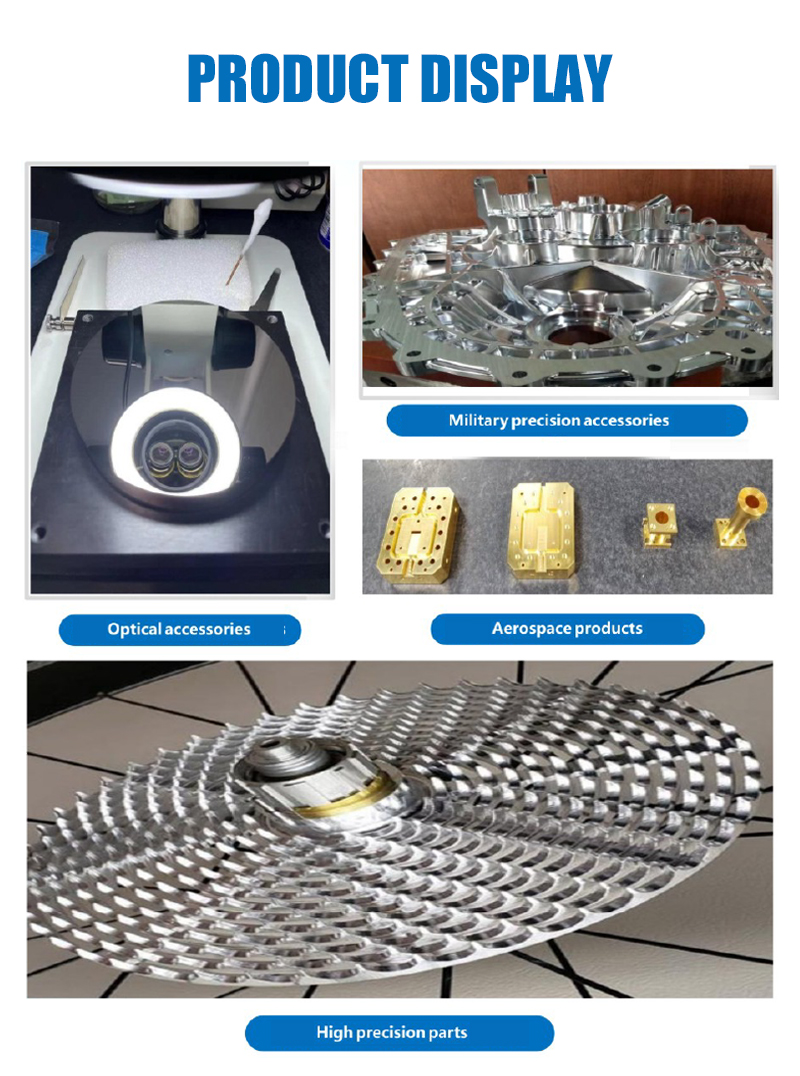

Cnc Machining Parts Precision Hardware Spring Stamping Precision injection molded parts: We can process various precision injection molded parts, including plastic parts, rubber parts, etc. These injection molded parts have precise dimensions and excellent physical properties, which can meet various customer requirements for precision injection molded parts.

What are the common quality problems in the CNC Stamping Process?

1. Dimensional Variation: Some of the parts also may not have the required dimensions because of the tools wearing out, an improper tool setting or poor feeding of material.

2. Spring back: However, based on stamping, the metal will return to its unstamped form and therefore it will not hold the formed shape hence developing dimensional errors.

3. Cracks and Tears: This can lead to formation of cracks or even a tear because of over stressing the material where it is thin or where corners are sharp.

4. Wrinkling: Can create wrinkles or folds – the depth of draw area is employed and when the material flows unevenly during stamping.

5. Poor Surface Finish: Pin holes, pits, tool marks, scratches, etc. may be on the surface of the part.

6. Incomplete Forming: It will not be under adequate pressure or the tooling used to shape the metal will not be adequate to create the right part with the right size and shape.

7. Stretching and Thinning: Depending on the extent of stretching, it may go beyond the elastic limit of the material leading to possibilities of thinning or weakening of the part in question.

8. Tool Wear and Breakage: Tools also can become rusty if not cleaned or if it constantly being used it will become rusty or brittle, or if the material being worked upon is so hard or abrasive.

9. Inconsistent Production: There may be fluctuations in all or some of the sections due to differences in the machine settings or change in the characteristic properties of material.

10. Scrap Generation: When the material is not cut properly, or when trimming is done inappropriately, then it leads to excessive scrap production.

To deal with these quality problems, it is necessary to establish efficient quality management programs such as periodic overhaul of the CNC machines tools, adequate training of the operators and constant enhancement of the production system.

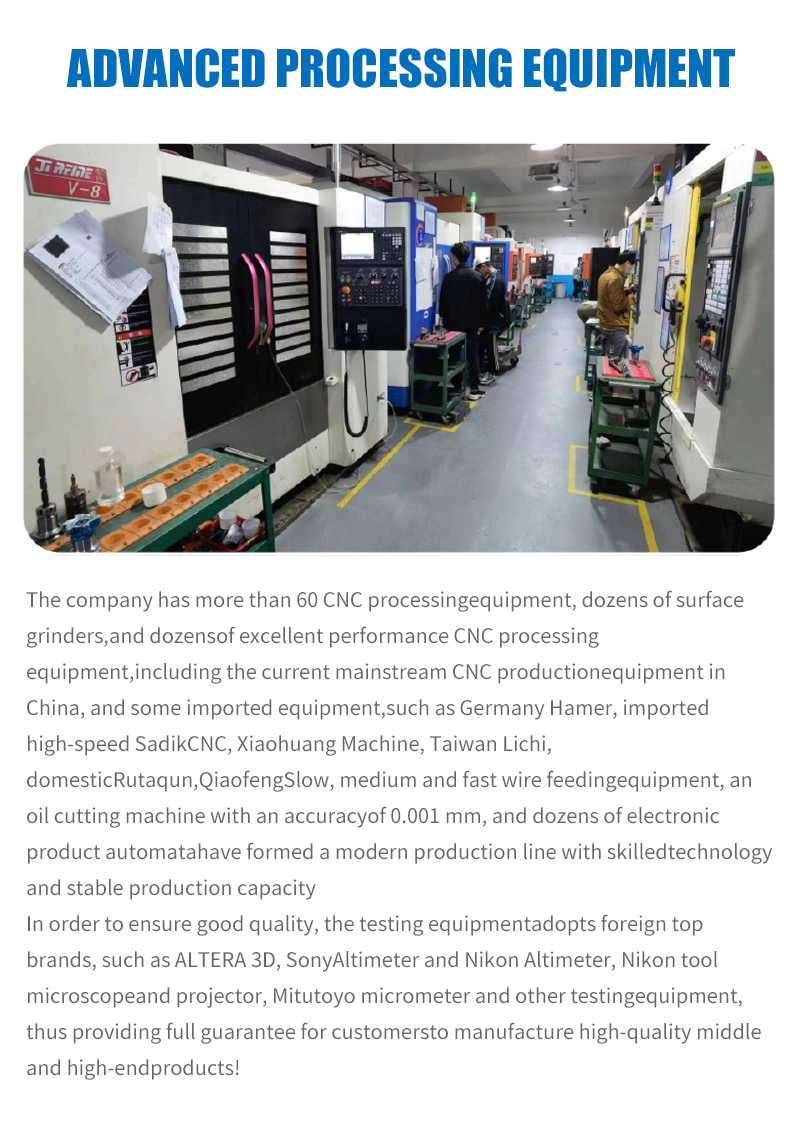

Founded in early 2007, the company is one of the industry's leading manufacturers of high-precision Precision Machining related hardware, Precision Parts,electronics, Plastic Injection Molds and products. It is committed to providing al-round professionalsolutions and satisfactory and thoughtful services to high-end customers around the world!

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.