Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The selection of gaps for hardware stretching molds should ensure that the punching reaches good cross-sectional quality, high dimensional accuracy, and a smaller punching force, usually resulting in a longer lifespan of the hardware stretching mold. The reasonable clearance of hardware stretching molds refers to a range of values, the maximum reasonable clearance and the minimum reasonable clearance.

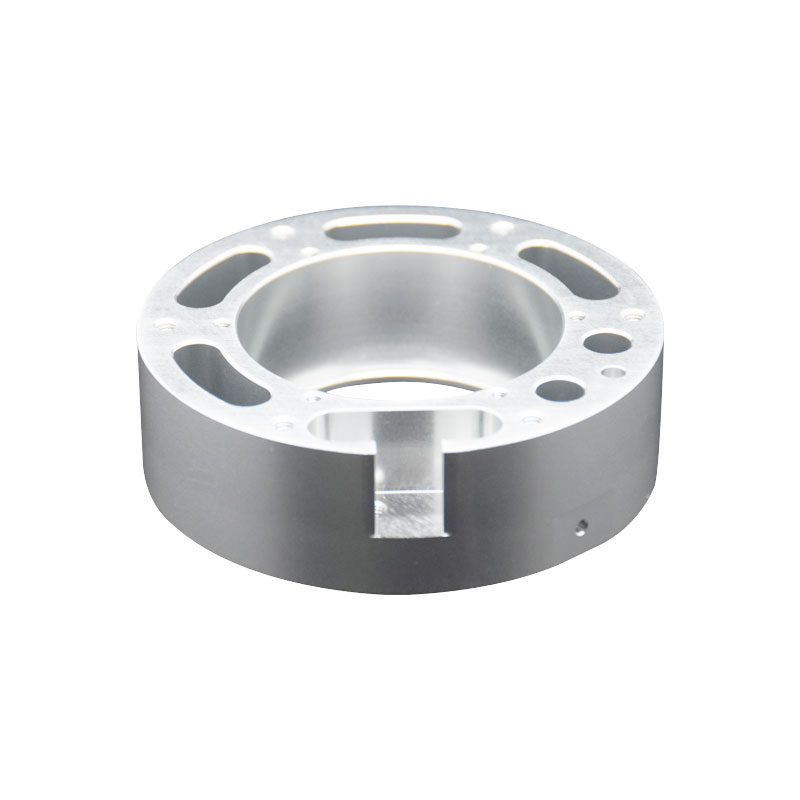

The determination of the gap of the hardware stretching mold is a comprehensive consideration of the impact of the gap on the cutting force, the lifespan of the mold, the quality of the cross-section, and so on. An appropriate range of gaps is selected as the reasonable gap of the hardware stretching mold. The upper limit is the maximum reasonable gap, and the lower limit is the minimum reasonable gap, which refers to a range value. When designing a hardware stretching mold for its body, it can be carried out according to the specific requirements of the workpiece and production. When there are no strict requirements for the cross-sectional quality of the workpiece, in order to improve the service life of the hardware stretching mold and reduce the punching force, a larger gap value can be selected. When the quality of the workpiece section and the manufacturing tolerance requirements are high, a smaller gap value should be selected.

The determination criteria for hardware stretching molds need to pay attention to the following points. The main factors affecting the gap value are the material properties and thickness. The harder or thicker the material, the larger the gap value.

Many 3D printing proponents claim that 3D printing is a good substitute for injection molding that requires a mold. Is it really? Let’s go and see what everyone’s opinions are like. Additive...

Model NO.: HW-386 Runner: Hot Runner Design Software: UG Installation: Fixed Certification: ISO Standard: HASCO Customized: Customized Trademark: HOWE or Custom Transport Package: Exported Wooden...

In order to ensure the safety of the plateau roads, the research and development work of the plateau new passenger cars initiated by the Ministry of Transport of the People's Republic of China to...

Model NO.: CKNC6180 Performance Classification: Economical CNC Machine Tools Certification: CE, ISO 9001 Condition: New Max.Swing Over Bed: 800mm Max. Swing Over Slide: 480 Max. Processing Lathe:...

Email to this supplier

ABOUT

PRODUCTS

Links

Follow Us

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.