Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

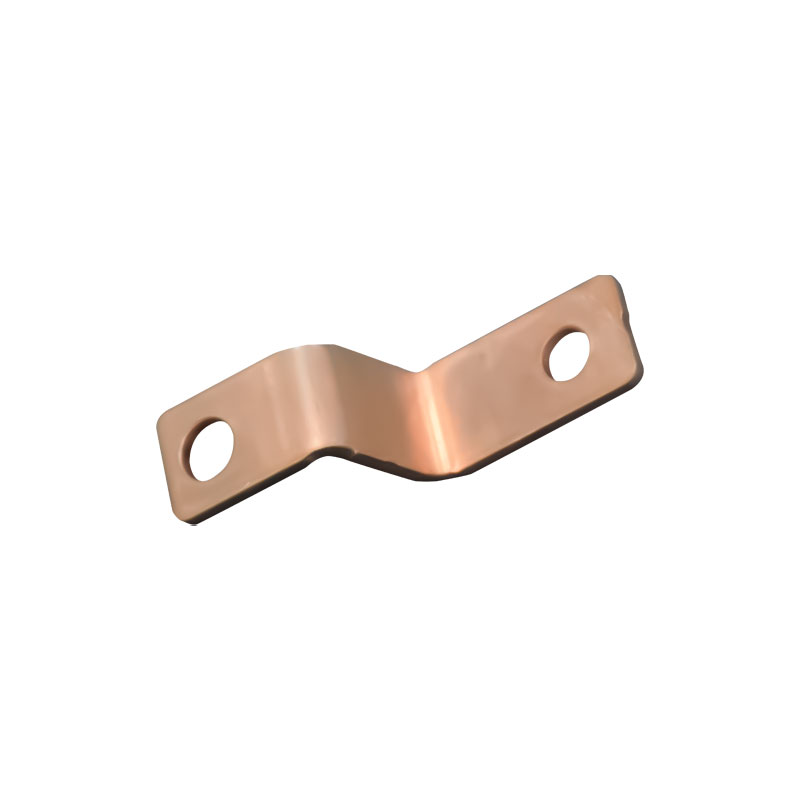

Sheet metal is a processing technique, and sheet metal processing is also known as sheet metal processing. This includes traditional methods and process parameters such as cutting and cutting, punching processing, bending and pressing forming, as well as various cold stamping mold structures and process parameters, working principles and operation methods of various equipment, as well as new stamping technologies and processes, and metal sheet metal processing of parts.

For example, iron barrels made from sheet metal processing, hand carts, stainless steel containers and tanks, ventilation pipes, elbows and small ends, circular areas, funnel forms, and so on.

Welding: Experienced operators choose machine automatic welding or manual welding based on different products and requirements.

Paint baking: The paint baking process also includes temperature, time, and paint color blending, which are all very rigorous, and this step is also crucial.

The welding seams of sheet metal parts should be firm and uniform, without defects such as false welding, cracks, penetration, cracks, and undercuts.

The length and height of the weld seam of the processed sheet metal parts shall not exceed the allowable requirements of the processed sheet metal parts.

The length of welding points for sheet metal processing parts is 8-12mm, and the distance between two welding points should be 50mm.

If there are special requirements for welding points in sheet metal processing on the drawings, they shall be executed according to the drawings.

After welding of sheet metal parts, the outer surface of the parts should be free of defects such as slag inclusion, air holes, welding overlap, bulges, and depressions. The inner surface defects should not be obvious and do not affect assembly. Important parts such as door panels and panels should also eliminate post welding stress to prevent workpiece deformation.

Key points of operation

Before work, check whether the large, small, and flat hammers have curled edges or scratches. The hammer handle should be firm, without cracks, and iron should be added. The installation should be firm, and there should be no defects in the chisel, punch, clamp, etc. The length of the chisel should generally not be less than 150mm, and it should be ground to a 60 ℃ blade angle. Defective tools are not allowed to be used.

Shovel, chop, rivet and other work are not allowed to be operated against people. When using pneumatic tools to work intermittently, the air door should be immediately closed and the shovel head should be taken out.

Cutting details, cutting of sheet metal, and cutting are commonly used techniques in sheet metal processing customization. Failure to cut properly can have a significant impact on subsequent processes. Therefore, in this process, it is necessary to ensure the quality of sheet metal processing by ensuring that the details are in place. In addition to product safety, the processing personnel should also pay attention to their own safety during operation, and the processing personnel should also pay attention to their own safety during operation.

The details in measurement should be known to the very least, and the difference is a thousand miles. Most sheet metal processing operations use measurement techniques. To ensure accurate measurement data, attention should be paid to the details in measurement. Differences in measurement may lead to poor product performance and quality, etc. Therefore, in order to ensure safety and stability, the details in sheet metal processing operations are very important.

Many 3D printing proponents claim that 3D printing is a good substitute for injection molding that requires a mold. Is it really? Let’s go and see what everyone’s opinions are like. Additive...

Model NO.: HW-386 Runner: Hot Runner Design Software: UG Installation: Fixed Certification: ISO Standard: HASCO Customized: Customized Trademark: HOWE or Custom Transport Package: Exported Wooden...

In order to ensure the safety of the plateau roads, the research and development work of the plateau new passenger cars initiated by the Ministry of Transport of the People's Republic of China to...

Model NO.: CKNC6180 Performance Classification: Economical CNC Machine Tools Certification: CE, ISO 9001 Condition: New Max.Swing Over Bed: 800mm Max. Swing Over Slide: 480 Max. Processing Lathe:...

Email to this supplier

ABOUT

PRODUCTS

Links

Follow Us

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.